csma

cementitious slag makers association

What is GGBS?

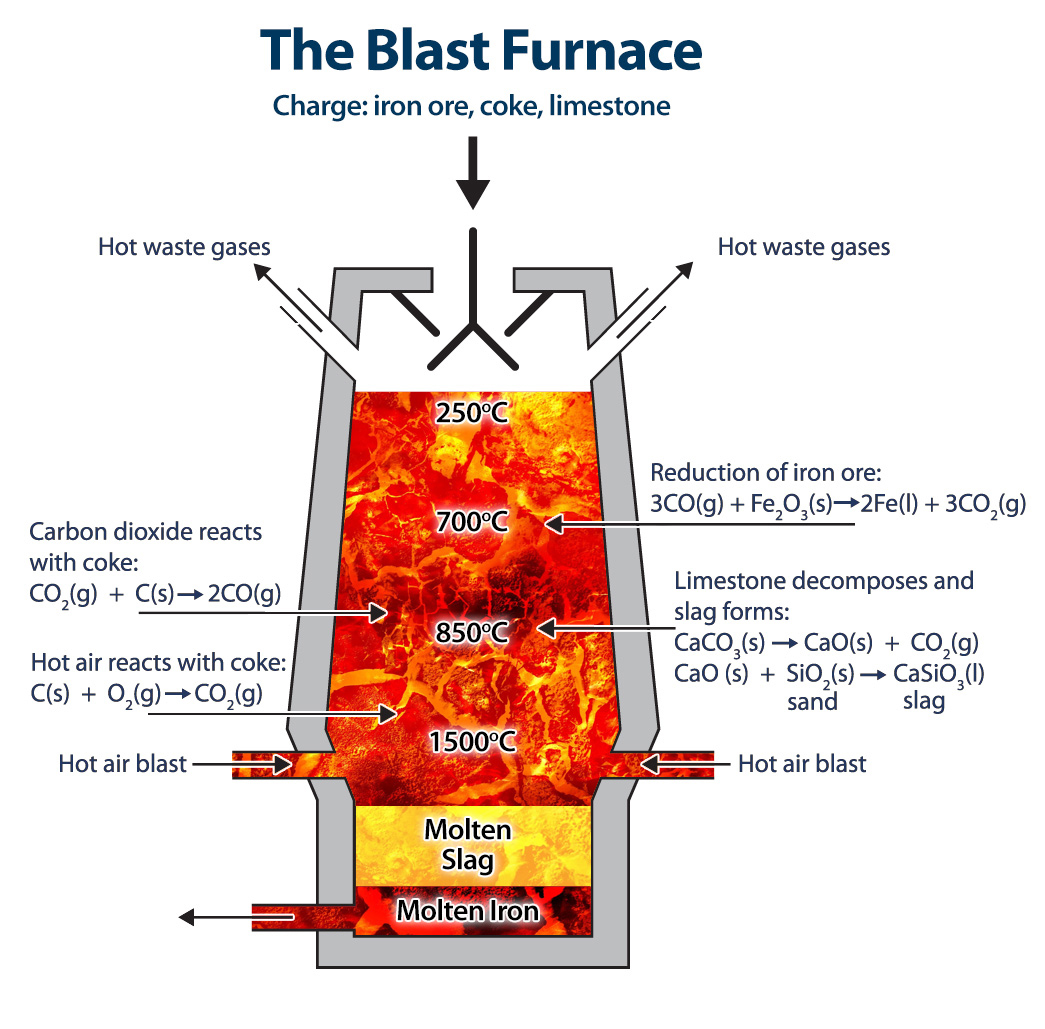

GGBS (Ground Granulated Blast-furnace Slag) is a cementitious material whose main use is in concrete and is a by-product from the blast-furnaces used to make iron.

Blast-furnaces operate at temperatures of about 1,500°C and are fed with a carefully controlled mixture of iron ore, coke and limestone. The iron ore is reduced to iron and the remaining materials form a slag that floats on top of the iron.

A by-product from the blast-furnaces used to make iron.

This slag is periodically tapped off as a molten liquid and if it is to be used for the manufacture of GGBS it has to be rapidly quenched in large volumes of water. The quenching optimises the cementitious properties and produces granules similar to a coarse sand. This ‘granulated’ slag is then dried and ground to a fine powder.

Although normally designated as ‘GGBS’ in the UK, it can also be referred to as ‘GGBFS’ or ‘slag cement’.

Typical chemical composition

| Calcium oxide: | 40% |

| Silica: | 35% |

| Alumina: | 13% |

| Magnesia: | 8% |

Typical physical properties

| Colour: | off-white |

| Specific gravity: | 2.9 |

| Bulk density: | 1000 - 1100 kg/m3 (loose) 1200 - 1300kg/m3 (vibrated) |

| Fineness: | >350m2/kg |